Description

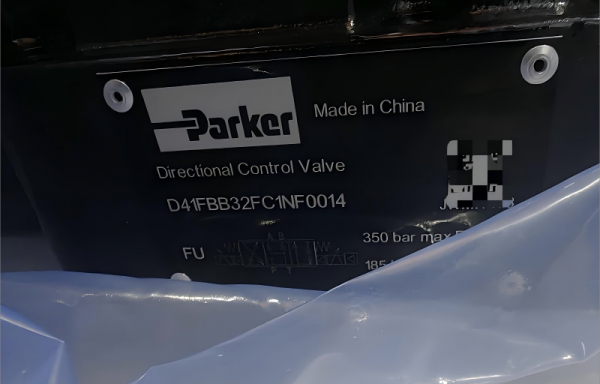

Parker D1VW030HNJW Directional Control Valve

The Parker D1VW030HNJW directional control valve, as a prominent member of the D1VW series, is designed to meet the demanding requirements of modern hydraulic systems. It combines advanced technology with reliable performance, making it an ideal choice for a wide range of industrial applications.

I. Technical Specifications Details

- Marking: Standard marking ensures easy identification and compatibility with various systems, facilitating seamless integration into existing hydraulic setups.

- Seal Material: Utilizes NBR (Nitrile Butadiene Rubber) as the primary seal material, providing excellent resistance to oils, fuels, and a wide range of chemicals. This ensures reliable sealing performance, preventing leakage and maintaining the integrity of the hydraulic system.

- Spool Position: Features a 2 – position design. The spool is spring – offset in position a and operated in position b. This configuration enables precise control over the flow direction of the hydraulic fluid, allowing for efficient operation of connected components.

- Operation Type: Adopts a direct operation mode, enabling quick and responsive control. It can promptly react to changes in the control signal, ensuring smooth and efficient operation of the hydraulic system.

- Maximum Flow Rate: Capable of handling a maximum flow rate of 70 L/min, providing sufficient fluid flow to meet the requirements of most hydraulic applications. This high flow capacity ensures that the connected equipment can operate at optimal performance levels.

- Input Voltage: Requires a 24 VDC power supply, which is a common and widely available voltage in industrial settings. This makes it easy to integrate the valve into existing electrical systems without the need for complex power conversion.

- Connection Type: Follows the connector standard as per EN 175301 – 803. This standardized connection ensures reliable electrical connections, reducing the risk of signal interference and connection failures.

- Solenoid Option: Comes with a standard solenoid, which offers a balance between performance and cost – effectiveness. The standard solenoid provides reliable actuation of the valve, ensuring consistent operation over time.

- Spool Code: The spool code is 030, which corresponds to a specific spool design that is optimized for certain flow characteristics and operational requirements. This code helps in identifying the correct valve for specific applications.

- Mounting Type: Utilizes a subplate mounting method, which provides a stable and secure mounting solution. The subplate mounting allows for easy installation and removal of the valve, facilitating maintenance and replacement when necessary.

- Orifice Size: The orifice size is not applicable (na), indicating that the valve’s flow characteristics are optimized through other design features rather than traditional orifice sizing.

- Actuation Type: Solenoid – actuated, which means that the valve is controlled by an electromagnetic solenoid. When the solenoid is energized, it moves the spool to change the flow direction of the hydraulic fluid, providing precise and reliable control.

- Product Series: Belongs to the Directional Control Valve series, specifically the D1VW series. This series is known for its high – performance and reliable operation in hydraulic systems.

- Weight: Weighs only 1.5 kg, making it relatively lightweight. This lightweight design simplifies handling during installation and maintenance, and also reduces the overall load on the hydraulic system.

- Maximum Operating Pressure: Can withstand a maximum operating pressure of 350 bar, making it suitable for high – pressure hydraulic applications. It ensures reliable operation even under extreme pressure conditions, providing long – term durability and performance.

- Maximum Operating Temperature: Operates effectively at a maximum temperature of 60 °C, while the minimum operating temperature is -20 °C. This wide temperature range allows the valve to be used in various environments, from cold industrial settings to warmer manufacturing plants.

- Seal Material (Alternative): Also features FPM (Fluororubber) as an alternative seal material, which offers excellent resistance to high temperatures, chemicals, and ozone. This dual – seal material option provides flexibility in choosing the most suitable seal for different fluid types and operating conditions.

- For Fluid Type: Designed for use with Water – Glycol fluids, making it suitable for applications where this type of fluid is used as the hydraulic medium. It ensures compatibility and reliable operation with Water – Glycol – based hydraulic systems.

- Function: Operates as a 2 – way valve, controlling the flow of hydraulic fluid in a single direction or blocking it, depending on the spool position. This simple yet effective function makes it suitable for a variety of hydraulic control applications.

- Port Connection: Uses the NG06 / CETOP 03 port connection standard, which is widely used in the hydraulic industry. This standardization ensures compatibility with a wide range of hydraulic components and systems, facilitating easy integration and installation.

- Mounting Position: The mounting position is unrestricted, although it is preferably installed horizontally. This flexibility in mounting position allows for easy installation in different hydraulic system layouts, providing convenience during system design and installation.

- Body Material: Constructed from cast iron, which offers high strength and durability. Cast iron is capable of withstanding the high pressures and mechanical stresses associated with hydraulic systems, ensuring the long – term reliability of the valve.

II. Product Performance and Advantages

- High Functional Limits: The D1VW series, including the D1VW030HNJW, offers high functional limits, with a maximum flow rate of up to 80 l/min (the D1VW030HNJW has a maximum flow rate of 70 L/min). This high flow capacity, combined with optimized flow passages, results in a very low, energy – saving pressure drop. This not only improves the efficiency of the hydraulic system but also reduces energy consumption, leading to cost savings over time.

- Versatile Spool Options: A wide variety of spools and options are available, allowing for the design of an unlimited number of hydraulic circuits. This versatility enables users to customize the valve to meet the specific requirements of their applications, providing tailored solutions for different hydraulic control needs.

- Smooth Operation: The D1VW series can be equipped with a soft shift option, which ensures smooth operation. An additional orifice in the solenoid anchor dampens the shifting time, reducing mechanical shock and wear on the valve and connected components. This results in quieter operation, longer component life, and improved overall system performance.

- Explosion – Proof Option: The D1VW*EE variant with explosion – proof solenoids is based on the standard D1VW series. It is not only ATEX certified (explosion – proof class is Ex e mb II T4 Gb for use in zone 1 and 2) but also equipped with IECEx compliant solenoids, which are certified in accordance with IECEx standard for equipment class 2 G. This makes it suitable for use in hazardous environments where the risk of explosion exists, such as in the petrochemical, mining, and oil and gas industries. All explosion – proof solenoids are of DC design, and valves for AC operation come with an integrated rectifier, ensuring compatibility with different power sources.

III. Applicable Market Areas

- Industrial Manufacturing: In various industrial manufacturing processes, such as metalworking, automotive production, and machinery manufacturing, the D1VW030HNJW directional control valve is used to control the movement of hydraulic cylinders, the operation of hydraulic motors, and the flow of hydraulic fluid in complex hydraulic systems. It ensures precise control over the machinery, enabling efficient production processes and high – quality output.

- Mining and Construction: In the mining and construction industries, where heavy – duty equipment is used, this valve provides reliable control of hydraulic systems. It can be used in excavators, loaders, and other construction machinery to control the boom, bucket, and other moving parts, ensuring smooth and efficient operation even in harsh working conditions.

- Oil and Gas Industry: In the oil and gas sector, where safety and reliability are of utmost importance, the D1VW030HNJW valve, especially the explosion – proof variants, is used in hydraulic systems for well – head control, pipeline operation, and other critical applications. It ensures the safe and efficient operation of equipment in hazardous environments, minimizing the risk of accidents and downtime.

- Food and Beverage Processing: In the food and beverage industry, where hygiene and cleanliness are critical, the valve’s compatibility with Water – Glycol fluids makes it suitable for use in hydraulic systems. It can be used to control the movement of conveyors, bottling equipment, and other machinery, ensuring smooth production processes while meeting strict hygiene standards.

IV. Application Scenario Examples

- Hydraulic Presses: In hydraulic press applications, the D1VW030HNJW valve is used to control the flow of hydraulic fluid to the press cylinder. By precisely controlling the flow direction and pressure, it enables the press to apply the required force for tasks such as metal stamping, forming, and assembly. The high flow rate and pressure – handling capabilities of the valve ensure fast and efficient operation of the press.

- Material Handling Systems: In material handling systems, such as conveyor belts and automated guided vehicles (AGVs), the valve controls the hydraulic motors that drive the movement of the equipment. It ensures smooth and accurate movement of materials, reducing the risk of damage to the products being handled. The soft shift option, if equipped, further enhances the smooth operation of the system, minimizing shock and vibration.

- Marine Applications: On ships and other marine vessels, the D1VW030HNJW valve can be used in hydraulic systems for steering, anchor handling, and other critical functions. Its ability to operate in a wide temperature range and withstand harsh marine environments makes it a reliable choice for marine applications. The explosion – proof variants can also be used in areas where there is a risk of gas or vapor explosion, ensuring the safety of the vessel and its crew.