Description

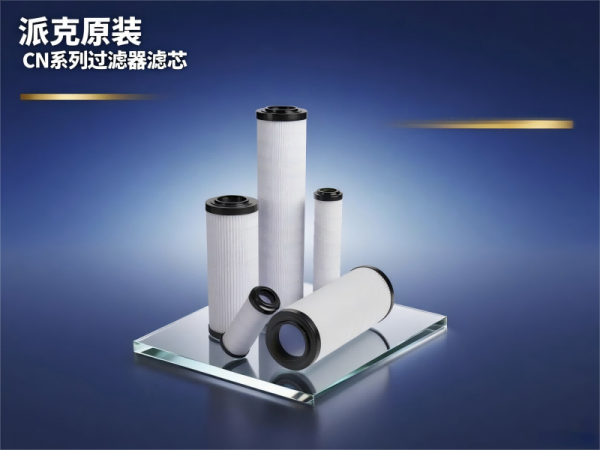

Parker 936719Q Filter Element – Medium Pressure Filter Cartridge, CN Series

## Product Basic Information

– **Model**: 936719Q

– **Series**: Parker CN Series Replacement Filter Element

– **Compatible Housing**: 80CN Filter Housing

– **Length Specification**: Length 2

– **Filter Element Type**: 20QE Ecoglass (Eco-friendly Glass Fiber Media Cartridge with No Metal Core)

– **Sealing Material**: Fluoroelastomer

– **Micron Rating**: 20 µm

## Core Product Advantages

1. **Dual Assurance of Original Eco-friendly Design and High Compatibility**

As a genuine filter element manufactured by Parker’s Hydraulic & Industrial Process Filtration Division EMEA, the 936719Q adopts Ecoglass eco-friendly media and is specifically engineered as a metal-free core cartridge for CN series filters with fixed internal cores. Its metal-free structure reduces weight by at least 50%, and after service, it can be disposed of environmentally via incineration—significantly lowering enterprises’ waste treatment costs. Meanwhile, it strictly complies with international filtration technology standards: its 20 µm filtration accuracy achieves “zero-gap” compatibility with the 80CN housing, avoiding issues such as oil leakage and unfiltered oil bypass caused by dimensional deviations. It efficiently intercepts harmful large-particle impurities of 20 µm and above in hydraulic oil, providing stable and reliable basic purification protection for medium-pressure hydraulic systems.

2. **20 µm Universal Precision for Heavy-Duty and Pre-Filtration Scenarios**

A micron rating of 20 µm is the optimal choice for “heavy-duty pre-filtration and regular protection” in hydraulic systems. It can accurately capture large-particle impurities that cause severe harm to equipment—such as 30-50 µm welding slag residues from hydraulic pipeline welding, 20-40 µm metal debris from heavy equipment wear, and dust clumps mixed in during outdoor operations—while maintaining strong anti-clogging performance. Compared to filter elements with 10 µm or higher precision, the 936719Q has a dirt-holding capacity increased by over 40%, extending the filter replacement cycle by 60% and reducing the frequency of equipment downtime for maintenance. Compared to filter elements with precision higher than 20 µm (e.g., 30 µm, 50 µm), it offers superior filtration performance, preventing direct impact wear from large-particle impurities on hydraulic pump vanes and cylinder seals. It is perfectly suitable for scenarios such as “heavy-duty pre-filtration”, “hydraulic system return oil pretreatment”, and “regular protection for large equipment”, balancing filtration efficiency and equipment operation continuity.

3. **Long-Length Design Meets High-Flow and High Dirt-Holding Requirements**

The Length 2 long-size specification increases the filter’s filtration area by more than 40% compared to the Length 1 short-size, significantly enhancing dirt-holding capacity. While maintaining 20 µm filtration accuracy, it can hold more large-particle impurities without clogging easily, making it particularly suitable for high-flow medium-pressure systems (e.g., return oil circuits of large injection molding machines, main hydraulic circuits of heavy construction machinery). It can stably adapt to a flow rate range of 0-600 L/min, avoiding filter overload and reduced filtration accuracy caused by excessive flow. This size can be directly installed in the 80CN housing without modifying equipment pipelines, not only meeting the oil circulation needs of high-flow systems but also reducing the frequency of filter replacement through its high dirt-holding capability. It lowers labor maintenance costs and is especially suitable for continuously operating industrial production lines and high-load outdoor operation equipment.

4. **Fluoroelastomer Sealing Adapts to Wide-Temperature and Complex Working Conditions**

The sealing material is Fluoroelastomer, which exhibits excellent temperature resistance, oil resistance, and corrosion resistance. It maintains reliable sealing performance within a wide operating temperature range of -20 to 120°C (-4 to 248°F) and has a maximum working pressure of 70 bar (1015 psi), easily coping with complex working conditions: whether it is high-temperature environments in industrial workshops (e.g., oil temperature of metal processing machines rising to 80-100°C), low-temperature outdoor conditions in winter (e.g., -20°C startup of construction machinery in northern regions), or scenarios involving partial synthetic oils, it can ensure leak-free sealing of the filter element, preventing oil contamination or pressure loss. Compared to Nitrile rubber seals, Fluoroelastomer has a service life extended by more than 2 times, reducing premature filter replacement caused by seal aging and further lowering maintenance costs.

5. **Eco-Friendly Features and Full-Cycle Cost Optimization**

The Ecoglass eco-friendly design and 20 µm universal precision of the 936719Q help enterprises reduce costs throughout the entire “procurement-use-disposal” cycle. In the procurement phase, there is no need to stock multiple high-precision filters for different working conditions—the 20 µm universal precision can cover most heavy-duty scenarios, reducing inventory backlogs. In the usage phase, the long-length design and high dirt-holding capacity extend the replacement cycle, reducing downtime for maintenance. In the disposal phase, the metal-free core eco-friendly structure allows for incineration disposal without harmful residues, complying with green production standards and lowering enterprises’ environmental treatment costs. Additionally, as a genuine Parker filter element, it maintains stable filtration performance, avoiding secondary contamination of impurities caused by media damage in non-genuine filters and reducing maintenance costs for hydraulic system failures, resulting in better long-term overall cost-effectiveness.

## Application Scenarios and Industries

### Core Application Fields

– **Compressor Lube Oil Pre-Filtration**: Intercepts 20 µm and above mechanical wear particles (e.g., metal debris from severe compressor bearing wear, rotor impurity clumps) in lube oil, protects core components of the compressor, and avoids compressor jamming and abnormal noise caused by large-particle impurities. It is suitable for industrial-grade heavy-duty compressors.

– **Hydraulic System Return Oil Pretreatment**: Serves as a “pretreatment filter element” for the return oil pipeline of medium-pressure systems, intercepting 20 µm and above impurities (e.g., cylinder wear debris, pipeline rust particles) generated during system operation. It prevents impurities from re-entering the oil tank for circulation, reduces oil contamination in the tank, lightens the burden on the main filter, and extends the service life of the main filter element.

– **Regular Protection for Machine Tools (Automotive Standard) Hydraulic Systems**: For heavy-duty machining tools of auto parts (e.g., rough milling machines for engine blocks, stamping equipment for gearbox housings), it filters 20 µm and above metal debris generated during processing, prevents wear to the machine tool’s hydraulic drive system caused by large-particle impurities, ensures stable equipment operation, and reduces machining dimension deviations.

– **Protection for Hydrostatic Drive Charge Pumps**: Provides 20 µm-level impurity interception for charge pumps of heavy-duty equipment, prevents large-particle impurities from entering the pump body and causing internal gear jamming, avoids unstable pressure in the hydrostatic system due to insufficient charge pump flow, and ensures the normal operation of heavy-duty equipment (e.g., large loaders, mining transport vehicles).

– **Protection for Mobile Equipment Hydraulic Circuits**: Adapts to the hydraulic circuits of small and medium-sized off-road construction machinery (e.g., excavators, harvesters), intercepts 20 µm and above dust and sand impurities mixed in during outdoor operations, prevents hydraulic valve jamming and cylinder oil leakage caused by impurities, reduces the frequency of outdoor maintenance, and improves equipment operation efficiency.

– **Injection Molding Machine Return Oil Filtration**: For the return oil circuit of large injection molding machines, it intercepts 20 µm and above metal debris from cylinder wear and plastic melt impurities generated during injection molding. It prevents impurities from contaminating the hydraulic oil in the tank, ensures clean oil when the injection molding machine starts next time, and reduces surface defects of molded products.

### Covered Industries

– **Industrial Manufacturing**: Fields including automotive manufacturing (hydraulic systems of heavy-duty machining tools), rubber & plastics (return oil circuits of large injection molding machines), metal processing (heavy-duty CNC machine tools, stamping equipment), and food & beverage (heavy-duty hygienic-grade hydraulic equipment, with eco-friendly disposal meeting industry standards), adapting to heavy-duty regular filtration needs.

– **Construction Machinery**: Agricultural machinery (large harvesters, tractors), construction equipment (excavators, loaders), mining machinery (small mining transport vehicles), and forestry machinery (logging equipment). They withstand complex outdoor working conditions and ensure reliable operation of hydraulic systems.

– **Government & Defense**: Hydraulic circuits of light military equipment (hydraulic systems of field communication vehicles, transmission circuits of small reconnaissance equipment), meeting the reliability and weather resistance requirements of military equipment and adapting to complex field environments.

– **Energy Sector**: Return oil filtration for hydraulic adjustment systems of new energy equipment (wind power equipment) and hydraulic circuits of thermal power auxiliary equipment (heavy-duty coal conveying equipment), ensuring long-term stable operation of energy equipment and avoiding equipment failures caused by impurities.

– **Transportation**: Auxiliary hydraulic systems of railway locomotives (brake return oil circuits, steering auxiliary circuits) and hydraulic systems of new energy heavy-duty buses. They intercept 20 µm and above impurities, improving the safety and operational stability of transportation equipment.

## Product Technical Parameters

– **Model**: 936719Q

– **Product Series**: Replacement Elements – CN Series

– **Filter Type**: Medium Pressure Inline Filter

– **Compatible Housing**: 80CN Filter Housing

– **Length**: Length 2

– **Filter Element Type**: 20QE Ecoglass (Eco-friendly Glass Fiber Cartridge with No Metal Core)

– **Sealing Material**: Fluoroelastomer

– **Micron Rating**: 20 µm

– **Maximum Working Pressure**: 70 bar (1015 psi)

– **Operating Temperature Range**: -20 to 120°C (-4 to 248°F)

– **Suitable Fluids**: Mineral oils, vegetable oils, and some synthetic oils

– **Adaptable Flow Rate Range**: 0 to 600 L/min

– **Eco-friendly Features**: Metal-free internal core, weight reduction of ≥50%, incinerable for disposal