Description

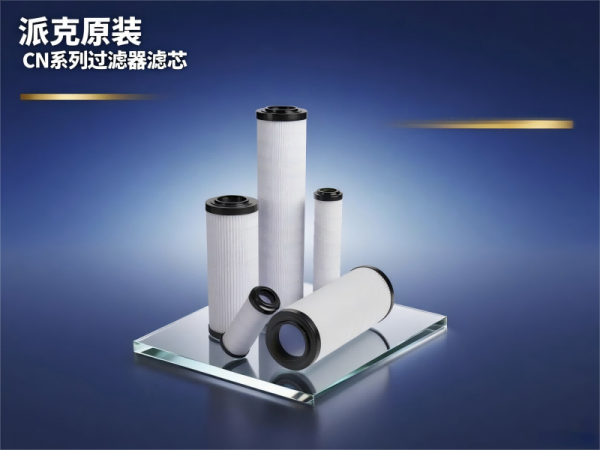

Parker 928935Q Filter Element – 15CN Series Medium Pressure Filter, Nitrile Seal & Microglass Media

## Product Basic Information

– **Model**: 928935Q

– **Series**: Parker CN Series Replacement Filter Element

– **Compatible Housing**: 15CN Filter Housing

– **Length Specification**: Length 1 (Short Size)

– **Filter Element Type**: 02Q Microglass (High-performance Glass Fiber Media Conventional Filter Cartridge)

– **Sealing Material**: Nitrile (Nitrile Rubber)

– **Micron Rating**: 2 µm

## Core Product Advantages

### 1. Genuine Microglass Media + Precise Compatibility, Protecting Precision Hydraulic Systems

As an authentic filter element manufactured by Parker’s Hydraulic & Industrial Process Filtration Division EMEA, the 928935Q adopts high-performance Microglass glass fiber media and is specifically designed for the 15CN filter housing. Its ultra-high filtration accuracy of 2 µm complies with international precision filtration standards, enabling it to accurately intercept tiny harmful impurities of 2 µm and above in hydraulic oil—such as 1-3 µm metal powder that easily clogs servo valve oil passages, 2-5 µm debris from precision machine tool wear, and colloidal particles generated by hydraulic oil oxidation. This prevents equipment jamming or accuracy degradation caused by micro-impurities. Meanwhile, the filter element’s dimensions achieve “zero-deviation” compatibility with the 15CN housing, and the nitrile rubber sealing structure fits tightly to the housing interface, eliminating oil leakage or unfiltered oil bypass issues. It provides “micron-level” purification protection for small and medium-sized precision medium-pressure hydraulic systems.

### 2. 2 µm Ultra-high Precision for Servo & Precision Manufacturing Scenarios

A micron rating of 2 µm is a core choice for hydraulic systems requiring “precision control and high cleanliness,” especially suitable for scenarios with strict hydraulic oil cleanliness requirements: In pilot lines for servo controls, it can intercept micro-impurities that may block the throttle holes of servo valves, ensuring precise and non-delayed response of servo mechanisms. In automotive-standard precision machine tools (e.g., engine cylinder head drilling machines), it filters ultra-fine metal dust generated during processing, avoiding hydraulic drive errors of machine tools caused by impurities and reducing the scrap rate of precision parts. Compared to filter elements with 5 µm or higher precision, the 928935Q offers over 60% higher filtration accuracy and can meet hydraulic oil cleanliness standards of NAS Class 6 or above, making it a key component for “wear prevention and failure prevention” in precision hydraulic systems.

### 3. Short-length Design for Compact Spaces, Balancing Precision & Installation Flexibility

The Length 1 short-size specification makes the 928935Q more compact, reducing installation space requirements by 40% compared to the Length 2 long-size filter element. It is particularly suitable for small and medium-sized hydraulic systems corresponding to the 15CN housing—such as compact hydraulic circuits of small hydraulic stations, mobile equipment, and local control oil circuits of precision machine tools where space is limited. It can be directly installed without modifying equipment pipelines, while maintaining the high dirt-holding capacity of Microglass media: Under the premise of 2 µm high-precision filtration, its dirt-holding capacity is 30% higher than that of ordinary filter elements with 2 µm precision, avoiding frequent replacements caused by the short-length design. It balances “space adaptability” and “service durability” to meet the continuous operation needs of small and medium-sized precision equipment.

### 4. Nitrile Rubber Seal for Conventional Working Conditions, Balancing Cost-effectiveness & Stability

The sealing material is Nitrile (nitrile rubber), which has excellent mineral oil resistance and adaptability to conventional working conditions. It maintains reliable sealing performance within a temperature range of -40 to 100°C (-40 to 212°F) and has a maximum working pressure of 70 bar (1015 psi), fully adapting to most industrial conventional working conditions: In hydraulic systems using mineral oil, the oil resistance of nitrile rubber is stable, and its sealing life is 1.5 times that of ordinary rubber. In normal-temperature workshop environments (e.g., auto parts assembly workshops, electronic equipment hydraulic stations), there is no need to worry about the impact of high or low temperatures on the seal, avoiding premature filter replacement caused by seal aging. Compared to fluoroelastomer seals, nitrile rubber offers higher cost-effectiveness in conventional working conditions, reducing the procurement costs for enterprises in conventional precision filtration scenarios.

### 5. Strong Full-cycle Adaptability, Reducing Comprehensive Costs of Precision Systems

The adaptability advantages and performance characteristics of the 928935Q reduce the comprehensive costs of enterprises from multiple dimensions: It is compatible with mineral oils, vegetable oils, and some synthetic oils, eliminating the need to stock separate filter elements for different oil types and reducing inventory categories. The short-length design enables easy installation, shortening replacement time by 50% compared to long-length filter elements and lowering labor maintenance costs. As a genuine Parker filter element, the stability of Microglass media avoids the “filtration failure-equipment maintenance” vicious cycle caused by non-genuine filter elements (with uneven media pore sizes), reducing high maintenance costs caused by precision component damage. At the same time, the long service life of nitrile rubber seals in conventional working conditions further extends the overall replacement cycle of the filter element, achieving the dual goals of “high-precision filtration” and “controllable costs.”

## Application Scenarios and Industries

### Core Application Fields

– **Servo Control Pilot Line Filtration**: Suitable for small and medium-sized servo hydraulic systems (e.g., servo drive circuits of precision injection molding machines, hydraulic joint control oil circuits of robots), it intercepts micro-impurities of 2 µm and above, preventing servo valve clogging, ensuring precise and rapid response of servo mechanisms, and avoiding equipment positioning errors caused by impurities.

– **Automotive Standard Precision Machine Tool Hydraulic Systems**: For precision machining tools of auto parts (e.g., gear grinding machines for gearboxes, crankshaft polishing machines), it filters ultra-fine metal dust generated during processing, ensures stable operation of the machine tool’s hydraulic drive system, reduces machining dimensional deviations of precision parts, and improves product qualification rates.

– **Precision Filtration for Small Hydraulic Stations**: As the main filter element of small hydraulic stations (e.g., hydraulic stations for electronic equipment assembly lines, precision hydraulic test benches in laboratories) matched with the 15CN housing, it stabilizes the hydraulic oil cleanliness to NAS Class 6 or above, avoids wear of small hydraulic pumps and cylinder seals caused by micro-impurities, and extends the service life of equipment.

– **Deep Purification for Off-line Filter Loops**: Used in auxiliary off-line filter loops of small and medium-sized equipment, it deeply purifies circulating hydraulic oil, removes micro-impurities and oxidized colloids accumulated during long-term use, delays hydraulic oil aging, extends the oil replacement cycle, and reduces oil procurement costs.

– **Hydraulic Systems of Medical Devices**: Suitable for some precision hydraulic equipment in medical devices (e.g., hydraulic drive units of small surgical instruments), the 2 µm high-precision filtration can meet the strict cleanliness requirements of medical devices for hydraulic oil, avoiding impurity contamination or equipment failures and ensuring the safe operation of medical devices.

### Covered Industries

– **Industrial Manufacturing**: Automotive manufacturing (precision parts machining tools), electronic equipment manufacturing (small hydraulic assembly equipment), and medical devices (precision hydraulic auxiliary instruments), adapting to the high cleanliness filtration needs of precision manufacturing scenarios.

– **Precision Machining**: Mold manufacturing (hydraulic drive systems of small precision molds) and aerospace parts machining (ultra-fine precision hydraulic machine tools), ensuring the hydraulic control accuracy of precision machining equipment.

– **Light Industry Equipment**: Packaging machinery (hydraulic circuits of high-precision packaging machines) and printing machinery (hydraulic control units of rotary printing machines), avoiding equipment operation failures caused by micro-impurities and improving the production efficiency of light industry.

– **Scientific Research and Testing**: Precision hydraulic test equipment in laboratories and hydraulic system R&D platforms in universities, meeting the high-standard cleanliness requirements of scientific research scenarios for hydraulic oil.

– **Transportation**: New energy small special vehicles (e.g., hydraulic steering systems of electric forklifts) and small auxiliary railway equipment (e.g., hydraulic circuits of track detection equipment), adapting to the compact space and precision control needs of small mobile equipment.

## Product Technical Parameters

– **Model**: 928935Q

– **Product Series**: Replacement Elements – CN Series

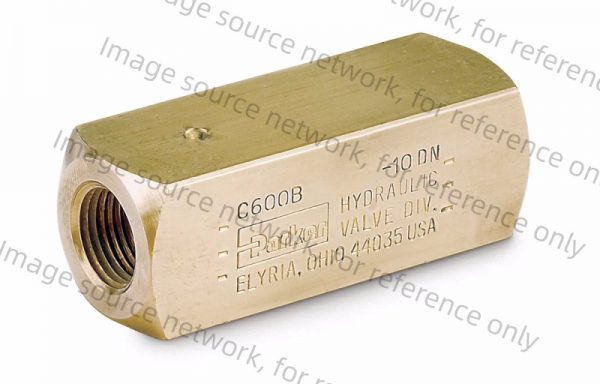

– **Filter Type**: Medium Pressure Inline Filter

– **Compatible Housing**: 15CN Filter Housing

– **Length**: Length 1

– **Filter Element Type**: 02Q Microglass (Conventional Filter Cartridge with Glass Fiber Media)

– **Sealing Material**: Nitrile (Nitrile Rubber)

– **Micron Rating**: 2 µm

– **Maximum Working Pressure**: 70 bar (1015 psi)

– **Operating Temperature Range**: -40 to 100°C (-40 to 212°F)

– **Suitable Fluids**: Mineral oils, vegetable oils, and some synthetic oils

– **Adaptable Flow Rate Range**: 0 to 600 L/min (matching the flow requirements of the 15CN housing)

– **Core Features**: High-performance Microglass media, 2 µm ultra-high precision, nitrile rubber seal for conventional working conditions, short compact design