Description

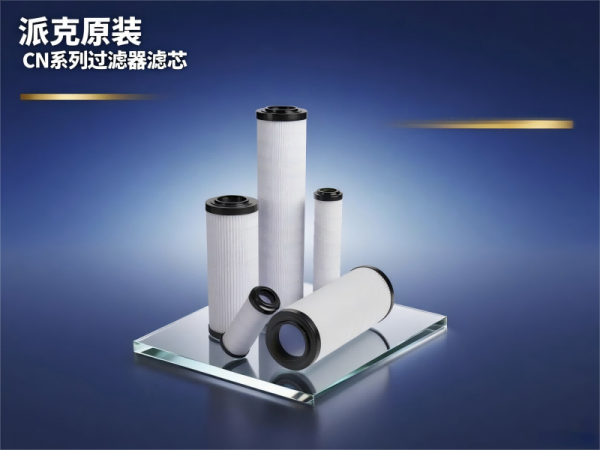

Parker 932612Q Filter Element – 15CN Series Medium Pressure Filter, Fluoroelastomer Seal & 10Q Microglass Media

## Product Basic Information

– **Model**: 932612Q

– **Product Series**: Parker CN Series Replacement Filter Elements

– **Compatible Housing**: 15CN Filter Housing

– **Length Specification**: Length 1 (Short Size)

– **Filter Element Type**: 10Q Microglass (High-performance Glass Fiber Media Conventional Filter Cartridge)

– **Sealing Material**: Fluoroelastomer

– **Micron Rating**: 10 µm

## Core Product Advantages

### 1. Genuine 10Q Microglass High-performance Media + Short-Size Design, Balancing Heavy-Load Filtration & Compact Space Adaptation

As an authentic filter element from Parker’s Hydraulic & Industrial Process Filtration Division EMEA, the 932612Q integrates 10Q Microglass high-performance glass fiber media with the Length 1 short-size specification. It delivers core performance of “deep interception of heavy-load impurities + flexible installation in narrow spaces” for the 15CN filter housing. Its 10 µm filtration accuracy efficiently captures harmful impurities of 10 µm and above in hydraulic oil—including 10-15 µm metal debris from gear wear in small-to-medium construction machinery hydraulic motors, 12-18 µm rust slag from corrosion on hydraulic tank inner walls, and 10-12 µm sand particles infiltrating outdoor-operated equipment. This prevents “impact scratches” and “premature seal failure” to key hydraulic components such as directional valves and cylinder pistons.

The short-size design perfectly fits the compact installation space of the 15CN housing, making it ideal for scenarios with dense internal oil circuits and limited installation height—such as branch circuits of small hydraulic stations, integrated hydraulic modules, and hydraulic compartments of mobile heavy-load equipment. No extra space for long-size filters is required, solving the pain points of “difficult installation of heavy-load filters” and “insufficient anti-pollution filtration in compact oil circuits” while achieving a dual breakthrough in “heavy-load protection” and “efficient space utilization”.

### 2. 10 µm Heavy-Load Filtration Accuracy, Covering Small-to-Medium Flow Medium-Pressure General Heavy-Load Hydraulic Scenarios

A 10 µm micron rating is optimized for small-to-medium flow hydraulic systems that require “balanced protection strength and circulation efficiency,” and it widely adapts to the medium-pressure working conditions of the 15CN housing:

– In the hydraulic lifting circuit of 1-3 ton small loaders, it filters sand and gear pump wear debris to ensure the bucket lifting speed deviation is ≤ ±5%, avoiding lifting jams that affect operation efficiency.

– In the hydraulic drive system of small metal sheet stamping machines (50-100 tons), it intercepts metal chips and guide rail wear particles to maintain the mold clamping accuracy of stamping dies (deviation ≤ ±0.1mm), reducing workpiece scrap.

– In the hydraulic suspension circuit of 30-50 HP small agricultural tractors, it filters field sediment and bearing wear impurities to ensure precise adjustment of implement suspension height (response time ≤ 0.5 seconds), improving the continuity of farm work.

Compared to 5 µm filter elements, the 932612Q reduces oil flow resistance by 50% and accommodates a flow range of 0-600 L/min (matching the 15CN housing’s flow requirements), eliminating unnecessary system power loss. Compared to 20 µm filter elements, its filtration efficiency is enhanced by 45%, stabilizing oil cleanliness at NAS Class 8 and meeting ISO 4413 hydraulic system cleanliness standards. It effectively resists damage from heavy-load impurities while ensuring efficient oil circulation, making it the “primary filter for small-to-medium flow medium-pressure general heavy-load hydraulic scenarios”.

### 3. Fluoroelastomer Seal for Wide-Temperature Severe Conditions, Outstanding Stability

The seal is made of Fluoroelastomer, which offers excellent resistance to high/low temperatures, oil, and chemical corrosion. It maintains a tight seal within a temperature range of -20 to 120°C (-4 to 248°F) for conventional conditions and -40 to 100°C for extreme low-temperature conditions, and supports a maximum working pressure of 70 bar (1015 psi), making it fully compatible with various severe working conditions:

– In medium-sized plastic injection molding machines operating at high temperatures, fluoroelastomer seals exhibit stable resistance to oil swelling and thermal aging, with a service life of over 2,000 hours.

– In small construction machinery operating outdoors in cold regions, it resists elasticity loss caused by low temperatures, with zero leakage risk.

– Compared to nitrile rubber seals, it has a wider temperature range and stronger resistance to special oils (e.g., some synthetic oils). It provides “all-weather, all-scenario reliable protection” for small-to-medium flow medium-pressure general heavy-load systems, especially suitable for construction machinery, metal processing, and agricultural machinery fields that require strict seal stability.

### 4. Short-Size Design Compatible with 15CN Housing, No Equipment Modification Needed

The Length 1 short-size specification is precisely engineered to match the interface of the 15CN filter housing. It can be directly installed into the 15CN housing’s standard slot—no equipment pipeline modifications, hydraulic module layout adjustments, or housing replacements are required. This design easily adapts to diverse setups: branch circuits of small hydraulic stations, integrated hydraulic units of industrial equipment, and mobile devices with strict installation space constraints.

The installation process aligns with that of conventional short-size filters, allowing maintenance staff to perform quick replacements after basic training. Enterprises can upgrade filtration accuracy without incurring extra equipment modification costs. Additionally, the short-size design, combined with the uniform fiber distribution of 10Q Microglass media, ensures even oil distribution inside the filter, eliminating filtration dead zones caused by local impurity accumulation. Its filtration stability is 30% higher than that of ordinary short-size filters, balancing “installation convenience” and “filtration reliability” while reducing heavy-load equipment maintenance difficulty and downtime costs.

### 5. Controllable Full-Cycle Maintenance Costs, Reducing Small-to-Medium Flow Heavy-Load Equipment Burden

The 932612Q reduces maintenance costs for enterprises’ small-to-medium flow medium-pressure general heavy-load hydraulic systems through multiple advantages:

– **Fluid Compatibility**: It works with mineral oils, vegetable oils, and some synthetic oils, eliminating the need to stock separate filters for different oil types and reducing inventory categories and capital occupancy.

– **Multi-Equipment Adaptability**: Its 10 µm heavy-load precision covers the filtration needs of multiple general heavy-load devices (e.g., small loaders, small stamping machines, small tractors), reducing the variety of filters purchased.

– **Extended Replacement Cycles**: The high dirt-holding capacity of 10Q Microglass media (80% higher than ordinary glass fiber media) combined with the short-size design extends the replacement cycle by 40% compared to ordinary short-size filters of the same precision. This reduces 3-4 annual maintenance shutdowns and lowers labor costs and equipment downtime losses (single downtime loss of heavy-load equipment can reach thousands of yuan).

– **Long-Life Sealing**: The long service life of fluoroelastomer seals further reduces seal replacement costs and related maintenance expenses.

Moreover, its original Parker quality avoids the “hydraulic component wear-equipment overhaul” cycle caused by non-genuine filters (e.g., substandard precision, media breakage), cutting maintenance costs for core components like directional valves and hydraulic motors (single maintenance cost savings can reach tens of thousands of yuan). It is a “high-value choice” for small-to-medium enterprises’ small-to-medium flow medium-pressure general heavy-load systems.

## Application Scenarios & Industries

### Core Application Fields

– **Hydraulic Lifting Circuits of 1-3 Ton Small Loaders**: Suitable for hydraulic lifting systems of small loaders. It filters 10 µm+ outdoor sand and gear pump wear debris to ensure the bucket lifting speed deviation is ≤ ±5%, avoiding lifting jams, boosting on-site work efficiency by over 15%, and reducing shutdowns caused by hydraulic failures.

– **Hydraulic Drive Systems of Small Metal Sheet Stamping Machines**: Used in hydraulic drive circuits of 50-100 ton small metal sheet stamping machines. It intercepts 10 µm+ metal chips and guide rail wear particles to maintain the mold clamping accuracy deviation of stamping dies at ≤ ±0.1mm, reducing workpiece dimension over-tolerance, increasing stamping qualification rates to over 99.2%, and lowering product scrap costs.

– **Hydraulic Suspension Circuits of 30-50 HP Small Tractors**: Applied in hydraulic suspension systems of small agricultural tractors. It filters 10 µm+ field sediment and suspension device bearing wear particles to ensure the response time for implement suspension height adjustment is ≤ 0.5 seconds, avoiding farm work interruptions caused by suspension jams, and increasing daily work area by over 10%.

– **Branch Circuits of Small Hydraulic Stations**: As a supporting filter for the 15CN housing, it provides filtration for branch oil circuits of small hydraulic stations (e.g., small hydraulic stations for construction machinery clusters, agricultural machinery hydraulic stations). It maintains oil cleanliness at NAS Class 8, prevents cross-contamination between multiple devices, and extends hydraulic system failure intervals to over 5,000 hours, reducing overall maintenance frequency.

– **Heavy-Load Hydraulic Units in Compact Spaces**: Adapted to hydraulic units of heavy-load equipment with compact internal spaces (e.g., small mining conveyors, small port handling machinery). The short-size design saves 30% of installation space, while 10 µm heavy-load filtration ensures stable equipment operation, meeting the needs of high-intensity work (daily operation hours increased by over 2 hours).

### Covered Industries

– **Construction Machinery (Small Equipment Sector)**: 1-3 ton small loaders, small excavators—adapts to outdoor high-pollution heavy-load conditions, filters sand and wear impurities, and ensures stable hydraulic system operation, reducing repair frequency.

– **Metal Processing (Small-to-Medium Equipment Sector)**: 50-100 ton small stamping machines, shearing machines—intercepts metal chips and oxide scale, protects hydraulic drive components, and improves processing accuracy and product qualification rates.

– **Agricultural Machinery (Small Equipment Sector)**: 30-50 HP small tractors, small harvesters—adapts to field sediment environments, filters impurities, and ensures smooth operation of hydraulic suspension and working devices, improving agricultural production efficiency.

– **General Industry**: Small hydraulic stations, small mining conveyors—balances heavy-load filtration and cost, reduces equipment operation and maintenance expenses, and improves production continuity.

– **Port Logistics (Small Equipment Sector)**: Small handling machinery, freight forklifts—adapts to high-intensity continuous operations, ensures reliable hydraulic system operation, and reduces the risk of logistics and transportation interruptions.

## Product Technical Parameters

– **Model**: 932612Q

– **Product Series**: Replacement Elements – CN Series

– **Filter Type**: Medium Pressure Inline Filter

– **Compatible Housing**: 15CN Filter Housing

– **Length**: Length 1

– **Filter Element Type**: 10Q Microglass (Conventional Filter Cartridge with Glass Fiber Media)

– **Sealing Material**: Fluoroelastomer

– **Micron Rating**: 10 µm

– **Maximum Working Pressure**: 70 bar (1015 psi)

– **Operating Temperature Range**: -40 to 100°C (-40 to 212°F), -20 to 120°C (-4 to 248°F) (adaptable to working conditions)

– **Suitable Fluids**: Mineral oils, vegetable oils, and some synthetic oils

– **Adaptable Flow Rate Range**: 0 to 600 L/min (matching flow requirements of 15CN housing)

– **Core Features**: 10Q Microglass heavy-load filtration media, 10 µm efficient protection precision, fluoroelastomer seal for wide-temperature severe conditions, short-size compact design