Description

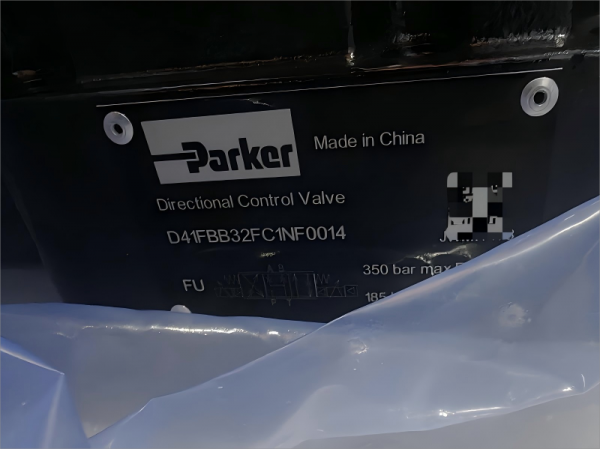

Parker D41FBB32FC1NF00 Proportional Valves

1. Product Positioning and Core Features

The Parker D41FBB32FC1NF00 belongs to the D*1FB OBE series of industrial hydraulic proportional valves, engineered for medium-flow high-pressure control scenarios. As an NG16/CETOP 07 rated pilot-operated proportional valve, it converts 0 to ±10V electrical signals into precise hydraulic flow regulation via a proportional solenoid. This design ensures dynamic response and stability, making it ideal for applications requiring sensitive control. The valve features a cast iron body with NBR seals, enabling long-term operation under 350 bar pressure. With an IP65 ingress protection rating, it resists dust and water spray in industrial environments, while onboard electronics simplify system integration.

2. Technical Characteristics Analysis

1. Control Precision and Dynamic Performance

Signal-Flow Mapping: A 0 to +10V input corresponds to P-B flow (200 L/min maximum), while -10 to 0V enables reverse flow (system-dependent), allowing linear flow adjustment for servo-level control. For example, in rubber tire processing, it segments signals to control mold closing speed in vulcanizers, preventing material overflow.

Rapid Response: With a 75 ms response time (25% faster than similar models) and hysteresis <5%, it ensures repeatability in high-frequency operations, such as reciprocating movements of machine tool worktables.

Pre-set Opening Point: The spool opening is set to 10% of the command signal to avoid flow surges at low inputs, ideal for soft-start applications like low-speed feeding in injection molding machines.

2. High-Pressure Adaptability

Pressure Boundaries: Operates at up to 350 bar, with a minimum pilot pressure of 30 bar + T/Y backpressure, suitable for high-pressure applications like metallurgical auxiliary equipment or medium-sized construction machinery. For instance, it regulates cylinder pressure in steel plate straightening machines to flatten 20mm-thick plates precisely.

Media Compatibility: Supports DIN 51524 hydraulic oils and water-glycol mixtures within 20–400 cSt viscosity. Using ISO VG32 oil (32 cSt at 40°C) allows stable operation from -25°C to 60°C, adapting to northern winter workshops.

3. Structural and Mounting Advantages

Modular Interface: NG16/CETOP 07 ports fit European-standard manifolds, and subplate mounting complies with DIN 24340, ISO 4401, etc., reducing integration costs. For example, it directly replaces old valves in machine tool retrofits without modifying the manifold layout.

Contamination Resistance: Meets ISO 4406 18/16/13 filtration standards, allowing ≤5μm particles to prevent spool jamming, crucial for rubber processing equipment exposed to material dust.

3. Detailed Technical Specifications

1. Connection and Mounting

Port Connection: NG16 / CETOP 07 (16mm bore), supporting internal/external pilot oil ports for flexible circuit layouts. External pilot drainage avoids backpressure interference in complex systems.

Mounting Type: Subplate mounting secures to manifolds via bolts, minimizing vibration effects and enabling easy maintenance without disassembling the entire circuit.

Electrical Connection: 6+PE pin interface (6 signal wires + ground) supports 18–30V DC (ripple <5%). Shielded cables are recommended to prevent EMI in industrial environments with multiple motors.

2. Flow and Pressure

Flow Rate: 200 L/min, suitable for medium-sized systems (e.g., 100-ton injection molding machines, small construction equipment booms), completing a 1.5m cylinder stroke in 10 seconds.

Pressure Range: 350 bar max working pressure; minimum pilot pressure 30 bar + T/Y backpressure. For example, with 10 bar backpressure in T/Y lines, pilot pressure must exceed 40 bar to fully open the main spool.

3. Media and Environment

Seal & Body Materials: NBR seals resist hydraulic oils and water-glycol (operating temp -20°C~100°C, limited by 阀体 to 60°C); cast iron body (tensile strength ≥250MPa) withstands 350 bar pressure and absorbs system vibrations.

Temperature & Viscosity: Media temp -25°C~60°C (low temp requires low-viscosity oil, high temp needs oxidation control); viscosity 20–400 cSt. ISO VG46 oil (46 cSt at 40°C) is recommended for optimal performance.

4. Performance and Reliability

Leak Rate: 200 ml/min at rated pressure (67% lower than D91 model), suitable for leak-sensitive applications like precision feed systems in metal-cutting machines.

Vibration Resistance: Complies with IEC 68-2-6 (5–2000Hz sine vibration, 10g RMS), maintaining stability during construction machinery operation.

5. Electrical and Protection

IP Rating: IP65 (dust-tight + water spray protection), suitable for wet rubber workshops or outdoor machines without extra enclosures.

Response & Hysteresis: 75 ms response (to 90% flow), 25% faster than D91; hysteresis <5% ensures consistent control during forward/reverse signal switching.

4. Application Scenarios

Rubber Tire Processing: Controls mold closing speed in vulcanizers, using 0–10V signals for “fast closing-slow holding” to prevent material spillage and improve tire yield.

Machine Tool Cutting Systems: Regulates worktable feed cylinder flow, with 10% pre-opening for smooth low-speed movement in precision boring machines.

Compact Construction Equipment: Balances digging force and speed in excavator boom operations using 200 L/min flow and 350 bar pressure.

Sheet Metal Forming: Adjusts press slide speed in stamping machines, combining with pressure sensors for multi-stage “fast approach-working pressure-holding” to enhance part precision.

5. Competitive Advantages

Cost-Effective Precision: Achieves 80% servo-valve accuracy at 30–50% cost, ideal for SMEs upgrading equipment.

Easy Maintenance: Pilot-operated design separates main and pilot valves, reducing repair time by 50% as only pilot components need replacement.

Energy Efficiency: Proportional control minimizes overflow losses compared to on/off valves, saving ~20% energy in partial-load conditions by adjusting pump output via signal input.

6. Series Comparison and Selection Guide

Model

D31FB (NG10)

D41FB (NG16)

D91FB (NG25)

D111FB (NG32)

Flow Rate

100 L/min

200 L/min

400 L/min

600 L/min

Ideal Use

Small tools

Medium injection molding, rubber equipment

Large presses

Marine deck machinery

Selection Tips: Choose D41FBB32FC1NF00 for 200 L/min flow and 350 bar pressure. Upgrade to D91FB for higher flow or downsize to D31FB for smaller systems.

Installation Notes: Maintain ISO 4406 18/16/13 cleanliness (NAS 8 for new systems); use independent pilot oil sources to prevent main circuit contamination.

7. Conclusion

The Parker D41FBB32FC1NF00 integrates pilot control, proportional solenoid actuation, and onboard electronics to deliver high precision, reliability, and cost-effectiveness in medium-scale hydraulic systems. Its standardized design and wide operational range support diverse industries—from rubber tire manufacturing to machine tooling—while energy-saving features and maintenance-friendly architecture reduce total cost of ownership.